SUSTAINABLE REACTION ENGINEERING

for carbon neutral industry

IRP1 is focused on chemical technologies that allow rapid decarbonisation of chemical industry and the chemical supply chain.

Our target is to deliver innovative solutions to direct utilisation of carbon dioxide as a feedstock, as well as to significantly increase the efficiency in conversion of methane to bulk intermediates.

We are also exploring the options for the emerging circular economy, by developing new transformations of molecules available in different bio-waste resources into high-value functional molecules.

Potential impact on carbon emissions reduction is evaluated by life cycle assessment tools.

FEATURED RESEARCH

Nano-structured catalyst design

One of the major directions for the development of integrated nanocatalysts (INCs) has been to integrate catalysts with different functionalities so that complex reaction systems could be carried out in one step with desired product yield. Synthesis of core-shell structured INCs is a commonly adopted strategy as it allows easy integration of core and shell materials with controlled compositions and functionalities to produce various INCs targeting individual reaction systems.

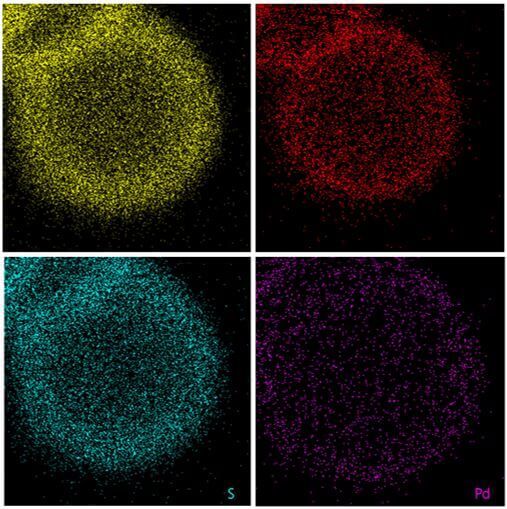

CARES researchers have developed a general synthetic approach to produce an organic-inorganic hybrid coating shell with homogeneously distributed organic functional groups.

Novel reactions and functional molecules

CARES researchers are working on developing a data-science approach to solving the problem of exploitation of bio-waste as a source of molecules. Their initial approach is to identify the potential “strategic” molecules – molecules that are important in the network of chemical transformations due to their connectivity to feedstocks and to useful products. Building on this work, the researchers will now proceed to develop a case study of analysing potential routes for utilisation of a bio-waste stream to produce a high-value functional product.

Novel reactors and process technology

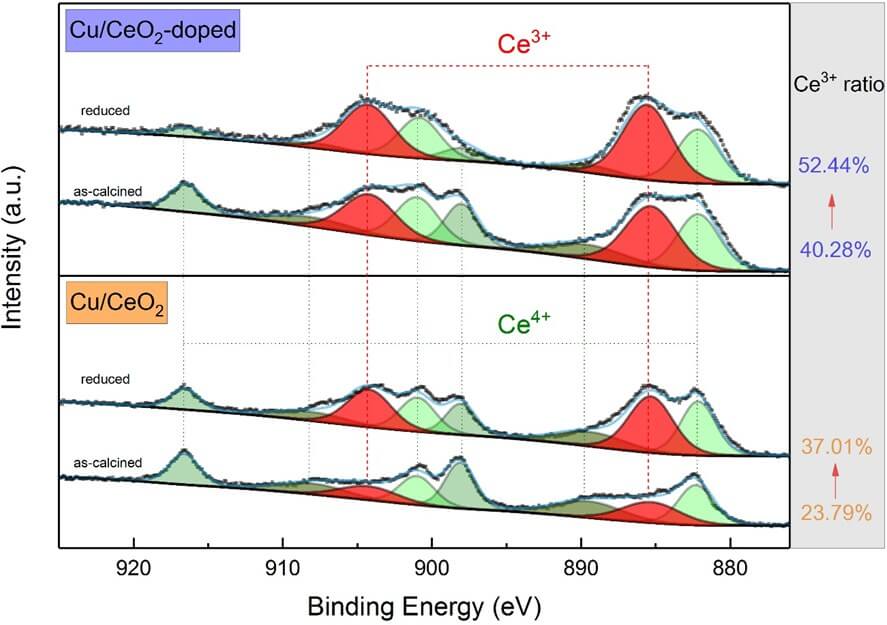

Work is being carried out on the modification of Cu supported on CeO₂ catalysts for the heterogeneous conversion of CO₂ into methanol. The pivotal role of Ce3+ species in the adsorption and activation of key surface intermediates has been revealed by incorporating proper dopants. In situ X-ray adsorption spectroscopy suggested the amount of Ce4+/Ce3+ redox pairs was not affected by the doping while the relative amount of Ce3+ was drastically increased. The same trend has also been observed by X-ray photoelectron spectroscopy. The adsorption of CO, key intermediates for CO₂ hydrogenation into methanol, was strengthened with enriched Ce3+ species.